What do we mean by Quality?

Whenever people from the world of giant from pump, motors, transformer, Generators, Hydro Generators, Traction Equipment, Specialize Motors, Auto Electricals, compressor, alternators, Panel and switch gear industries think about Quality – they first think about MADHAV COPPER. A sense of satisfaction and quality of trust that naturally come on their faces, have been earned by MADAHV COPPER through dedicated team, hard work and total commitment to meet customers toughest requirements – many a times working together with them.

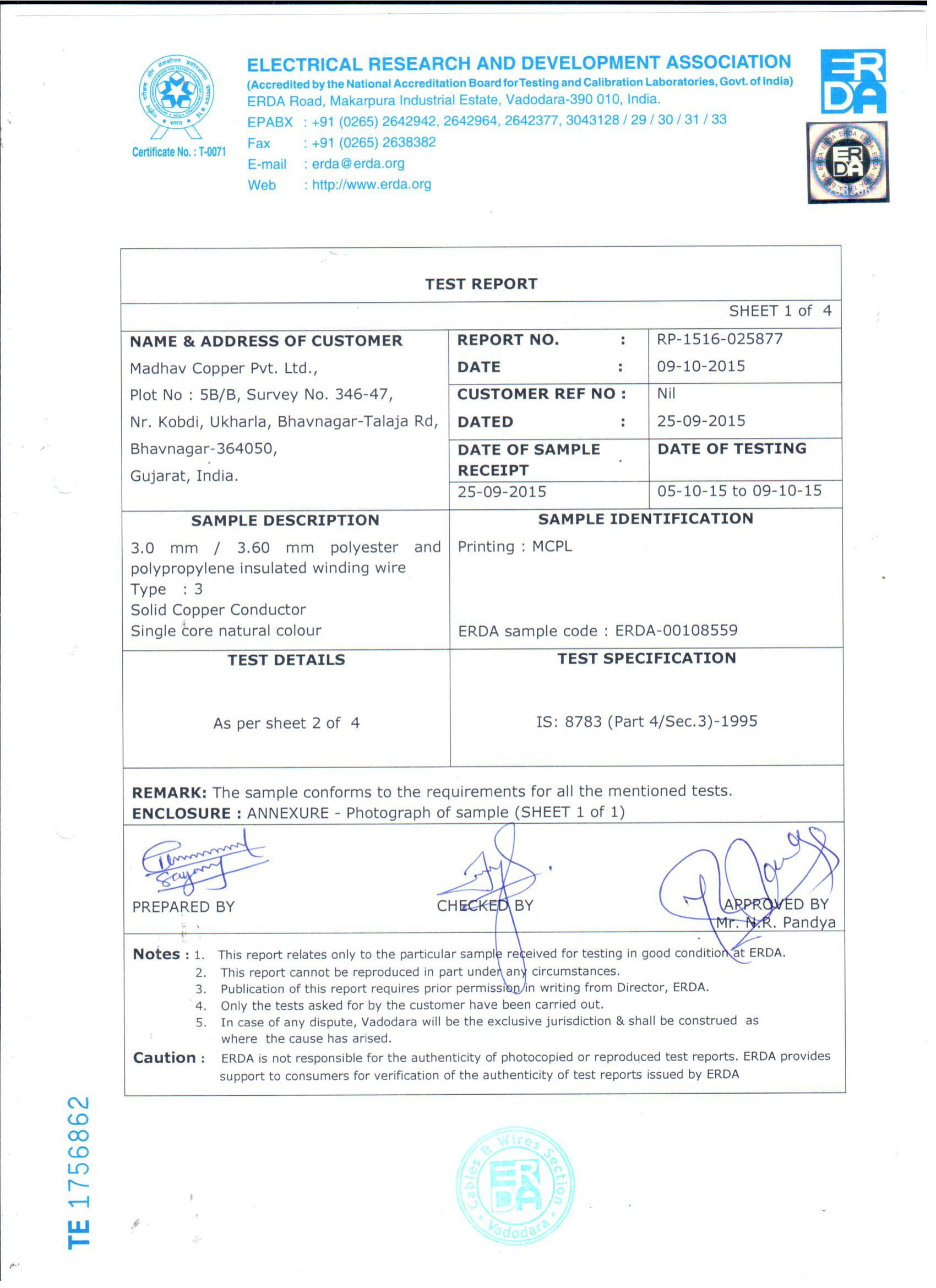

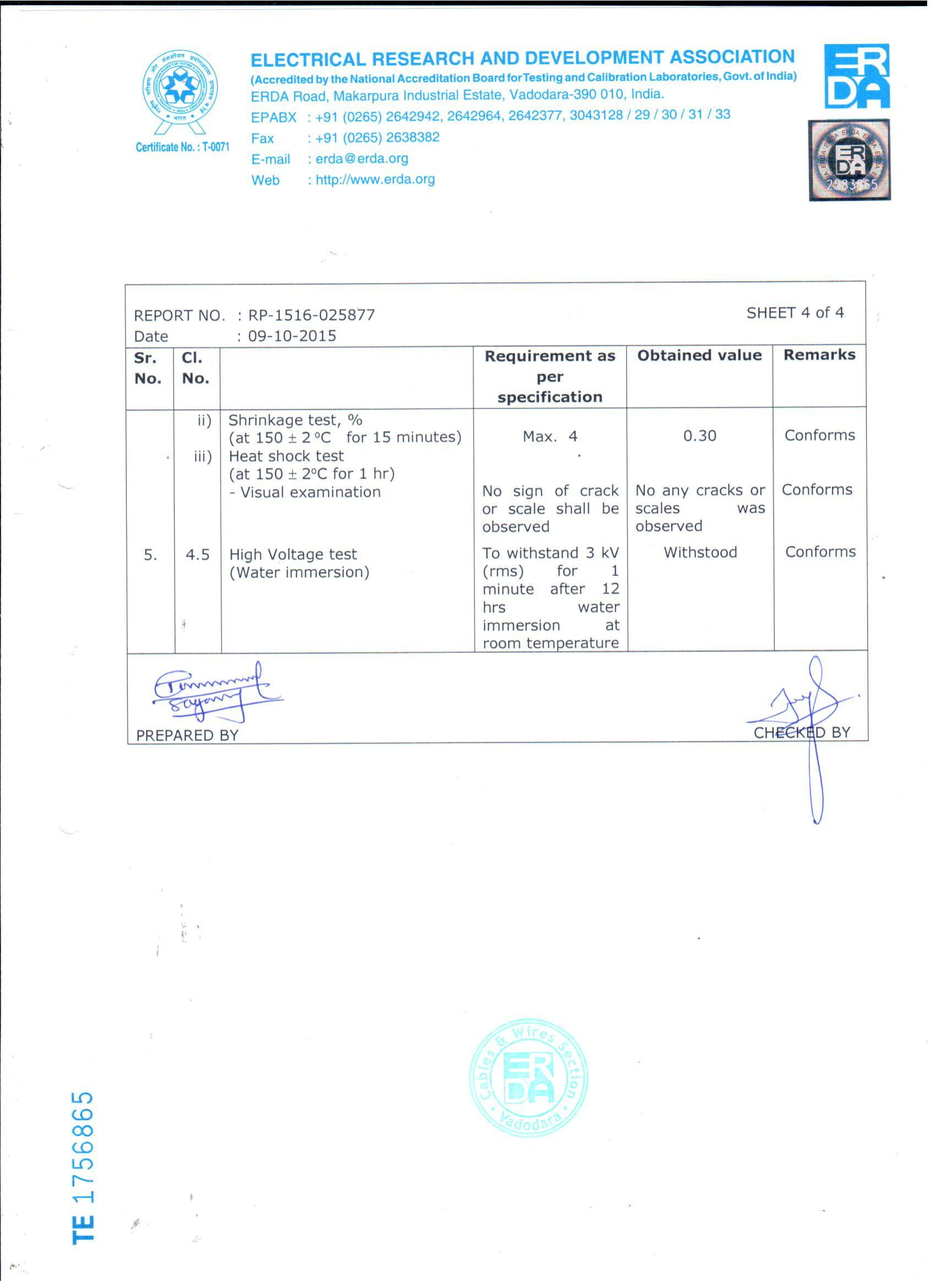

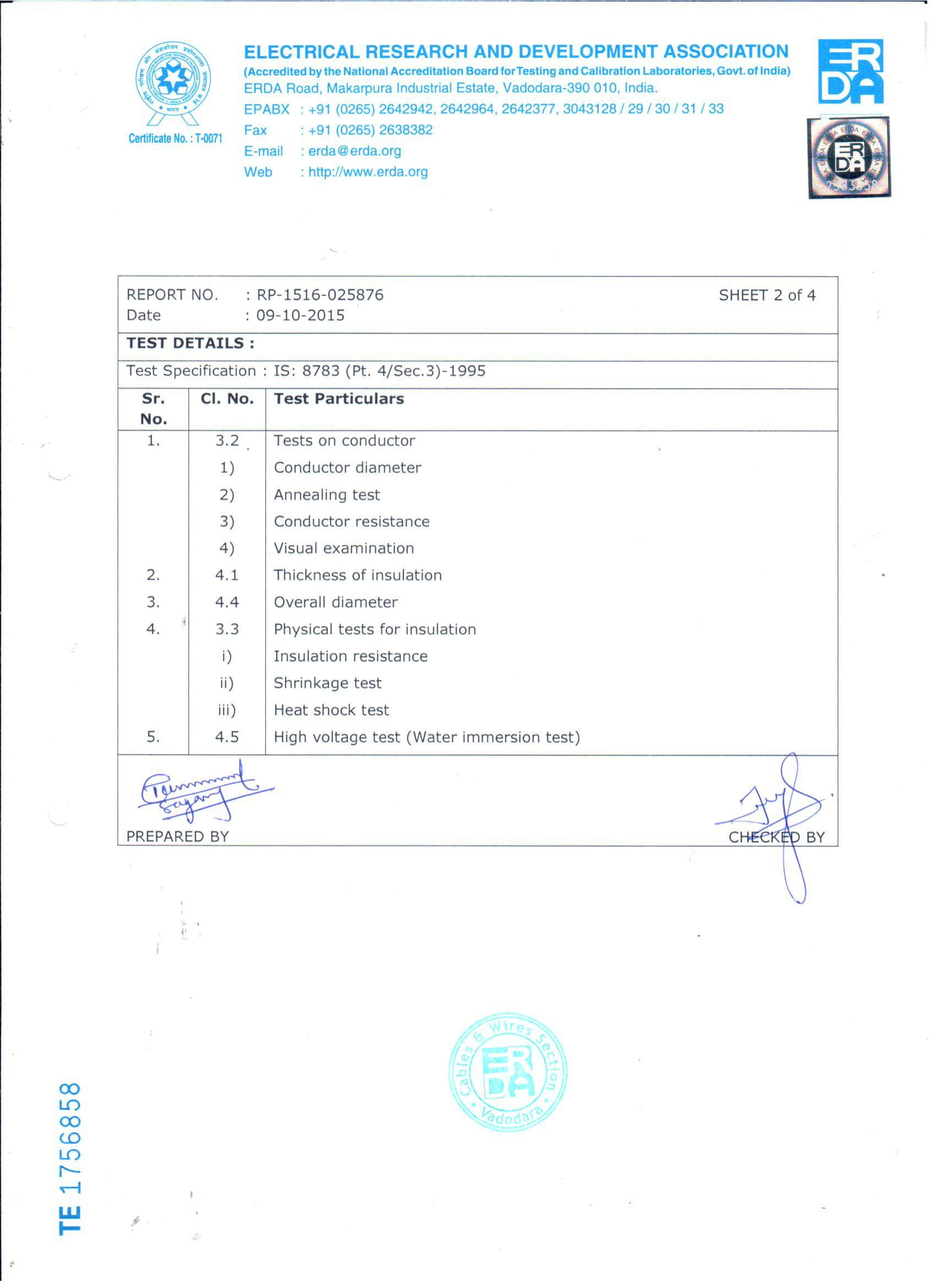

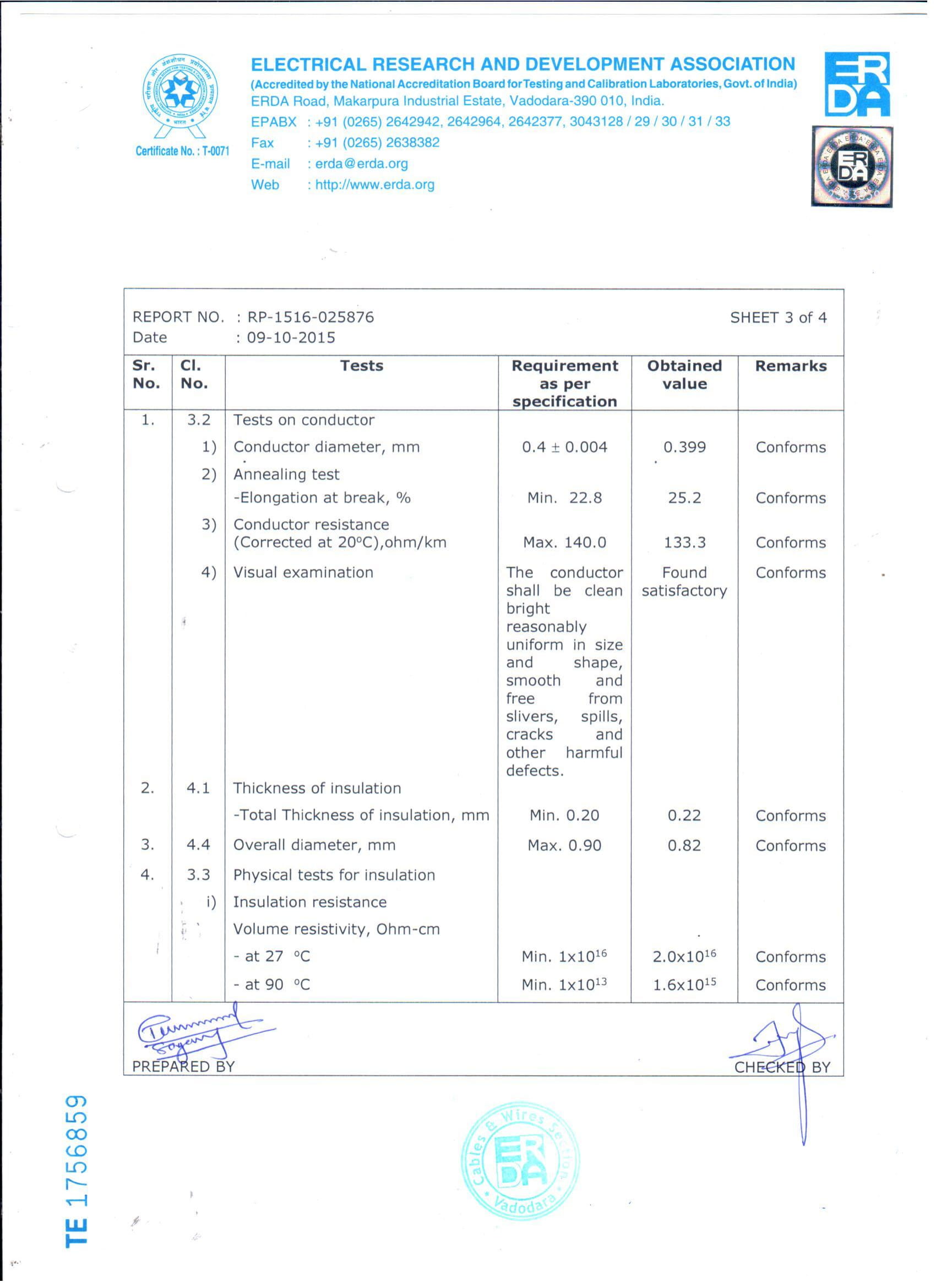

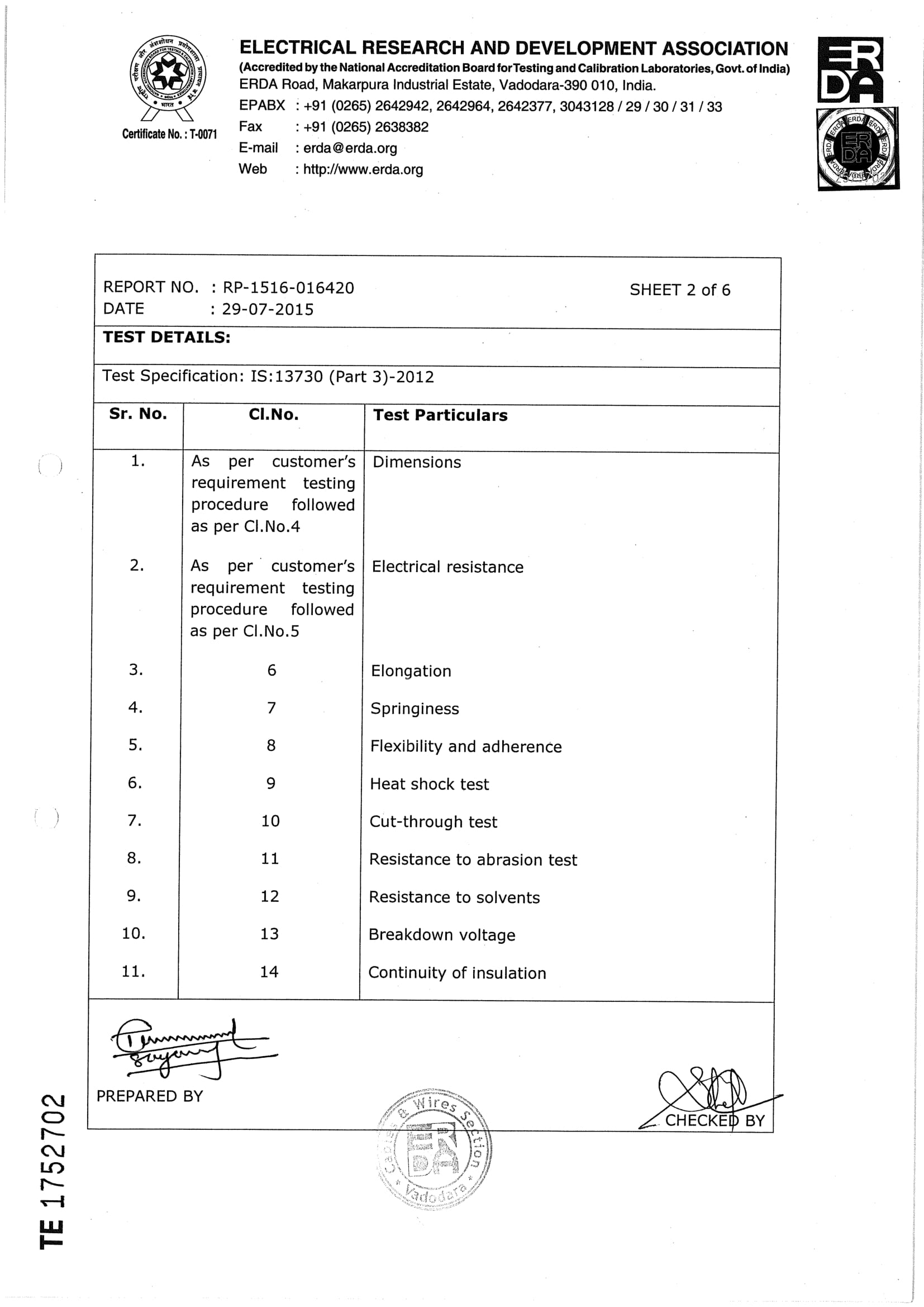

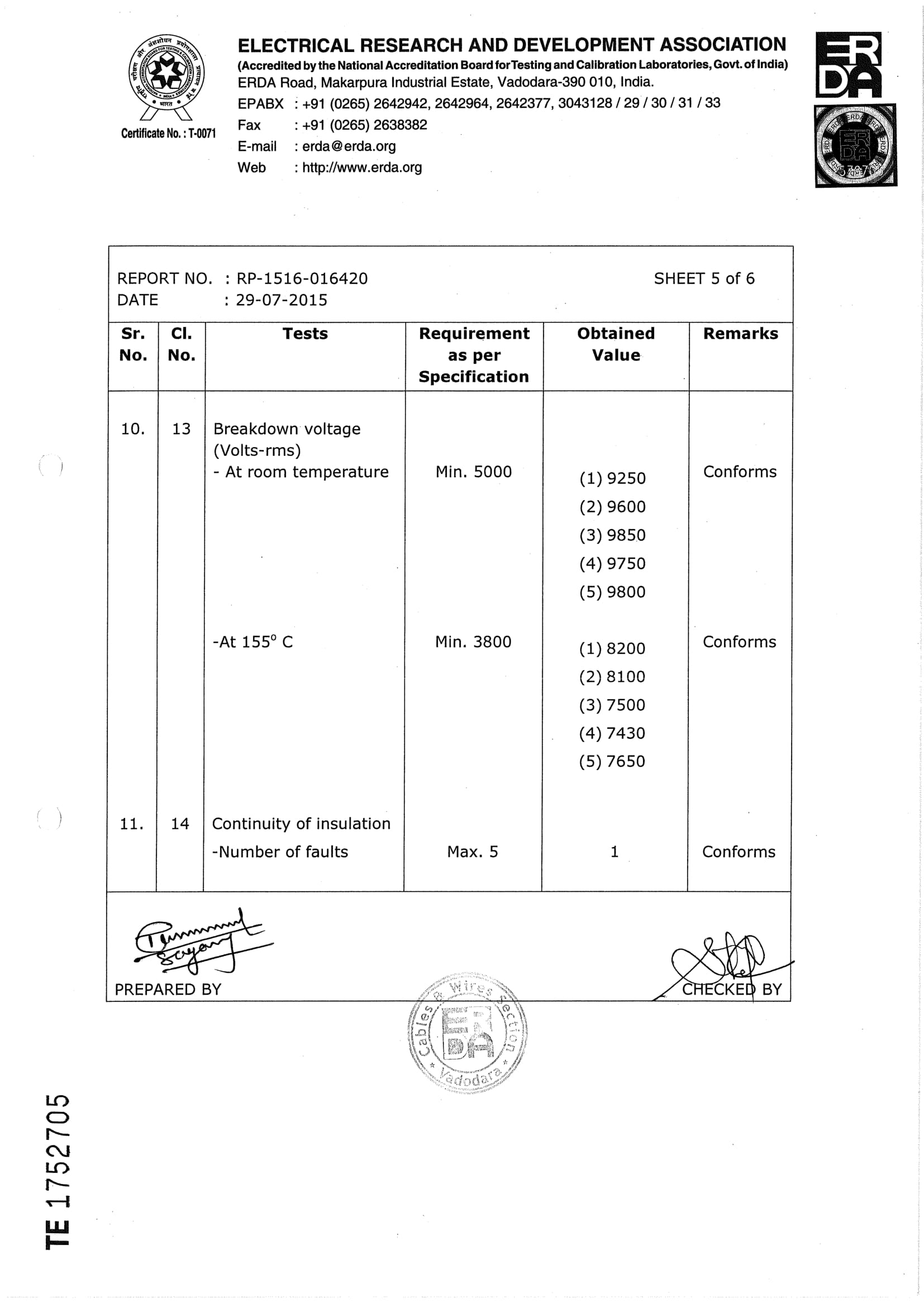

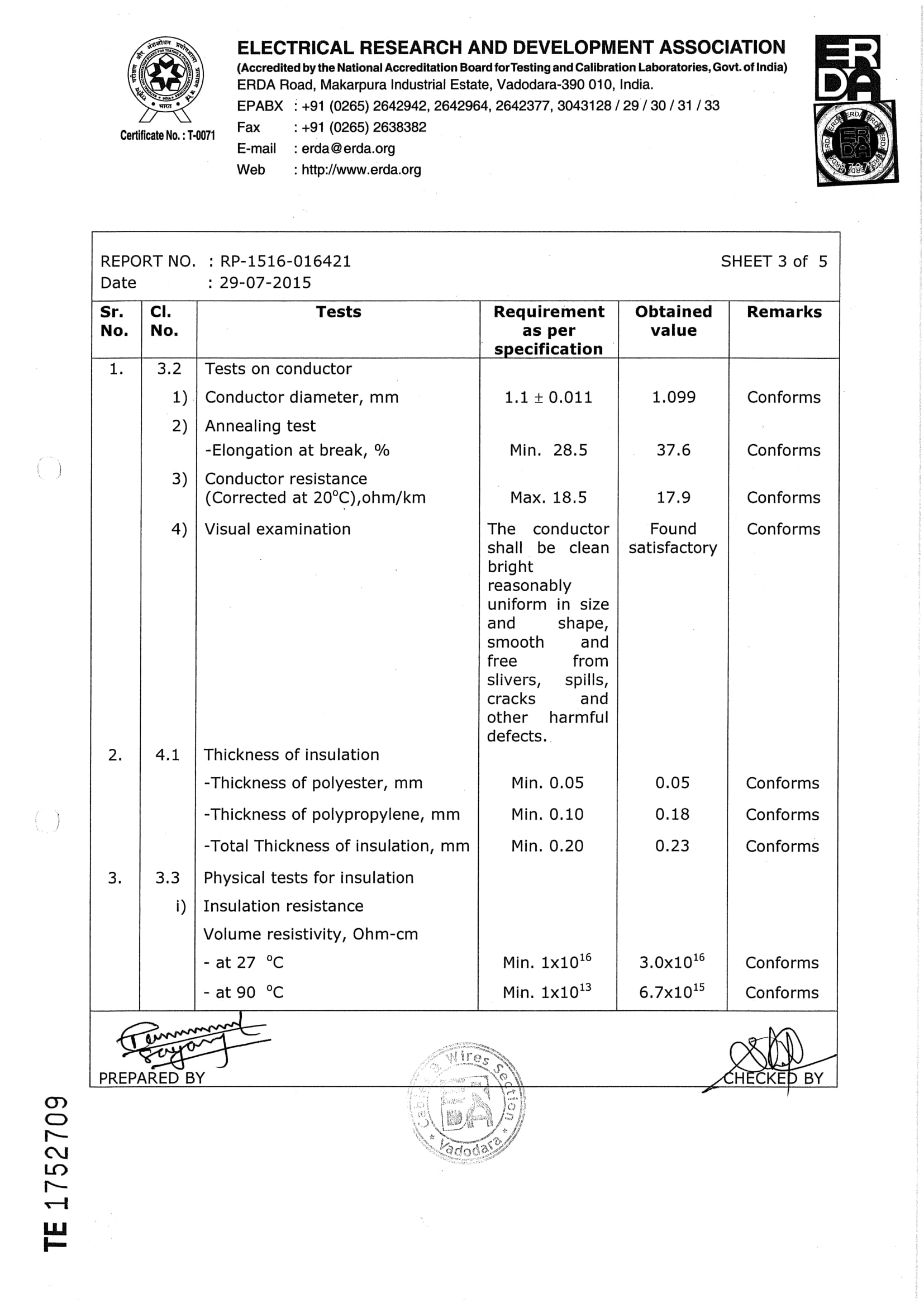

It would not have been possible without rigors of intense Research & Development and impeccable Quality management systems to achieve such result. The carefully selected test facilities are, therefore, one of the best available in the world. The comprehensive set of tests, as listed in MADHAV COPPER Quality Plan encompasses requirements of all latest global specifications related to the product.

The journey of assuring quality begins right at the receiving stage. Conductor materials constitute over 99.997% pure ETP/ OFC Grade of Copper with Conductivity of IACS 101%– hence rightly deserve the best attention. Spectrometer Metallographic, Oxygen Analyser to maintain < 5 ppm oxygen content, latest PC based Die electric dissipation for Tan -d and torsion tests ensure that only the flawless copper rods are made available for processing. While the first process of Extrusion, Drawing, Round-wire drawing (achieved by special rotating die) delivers perfectly round, rectangular, bus bars, profile and smooth - surface, bright product to the next process of Enamelling, tapping, Extrusion and Copper Fabricated product, it is the unmatched process control at this second stage which produces enamelled wire, Copper Tapped Conductor, Copper Busbars and Copper Fabricated Product with incredibly narrow tolerances of less than ± 1% in size, in insulation covering, corner radius, flatness, and wind ability – against an internationally accepted tolerance.

This not only consistently gives wire, Copper Tapped Product and copper fabricated product of uniform dimensions, it also helps in improve the designed eventually, size of the electrical engineering, Magnetic field, stray flux, eddy currents, loss generation, temp rise, hot spot, surface oxidation, internal & external cooling, hydraulics, mechanical design, short circuit, noise, transport, electric network, impulse tests, voltage transients, resonance, dielectric design, etc,.

The most exhaustive tests are conducted on the wire, Tapped Copper Conductor and copper fabricated products when they are coated with enamel/ Poly wrap film during this process. On-line HV testers, capable of detecting each and every pin-hole fault (in case, pops-up on enamelled, Insulated or Tapped Conductor during coating), prevent any bad spool from going to the next stage. MADHAV COPPER, at this stage, does not merely conduct customer-specified and tests as per International standard, but also performs many special tests, which merely developed by Madhav Copper to reinforce confirmation to customer requirements.

Tan-delta to determine enamel curing, Megger to determine insulation Tapping strength and HV/ BDV to determine insulation ability to sustain voltage at break down, Heat Shock/ Cut through to determine thermo mechanical strength of insulation, Spectro analysis to determine purity and metallurgy of copper, UTS to determine tensile strength, Conductivity to determine % of Conductivity in IACS, Oxygen Analyser to determine content of Oxygen are some of such tests that are included in MADHAV COPPER Quality Plan.

Finally, the Customer satisfaction survey and valuable feedback from customers form an essential part of MADHAV COPPER’s routine life. Being an ISO 9001: 2015, ISO 14001:2015 certified company, it strongly believes in what ISO says with regards to Customer satisfaction. MADHAV COPPER understands and respects the Voice of Customer and acts promptly on any issue related to its product, quality, logistics, technical and innovation – as MADHAV COPPER is not just a supplier to its customers, it is an associate business partner in their growth.

_page-0001.jpg)

_page-0001.jpg)